I. Principle of Operation: Electrofusion welding involves the use

of specialized fittings that have embedded heating elements. The

electrofusion welding machine supplies an electrical current

through these heating elements, generating heat that melts the pipe

and fitting surfaces. As the melted material cools, it fuses the

pipe and fitting together, creating a strong joint.

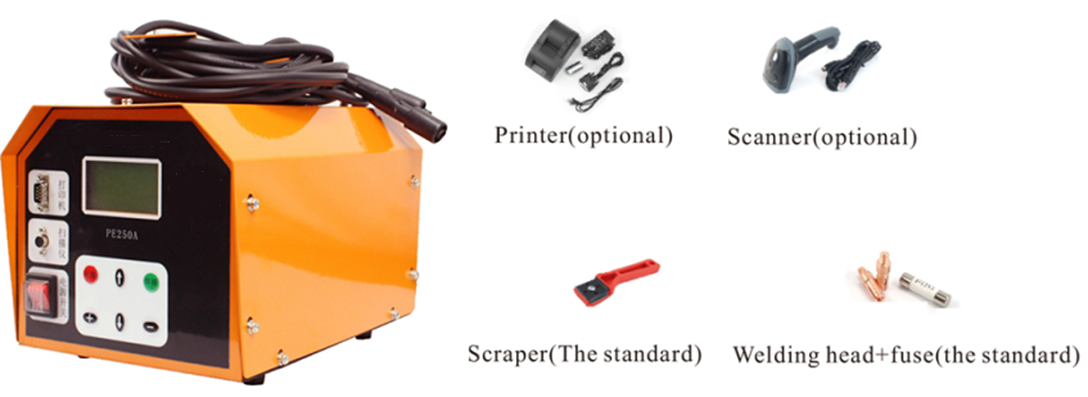

II. Machine Components: An electrofusion welding machine typically

consists of the following components:

1) Control Unit: The control unit houses the necessary electronics

and controls for operating the machine. It allows the operator to

set and monitor welding parameters such as welding time,

temperature, and voltage.

2) Electrofusion Unit: The electrofusion unit is responsible for

supplying the electrical current to the heating element in the

fitting. It delivers the precise amount of current required for the

specific fitting and pipe being welded.

3) Clamping Mechanism: The machine has a clamping mechanism that

securely holds the pipe and fitting in place during the welding

process. This ensures proper alignment and contact between the

surfaces to be fused.

4) Data Recording: Some electrofusion machines have data recording

capabilities, allowing operators to store and retrieve welding

parameters and joint information for quality control and

traceability purposes.

III. Welding Process: The electrofusion welding process typically

involves the following steps:

1) Preparation: The pipe ends and fitting surfaces are cleaned and

prepared to remove any contaminants or dirt.

2) Marking and Insertion: Electrofusion fittings have marked

insertion depths indicating how far the pipe should be inserted.

The pipe is inserted into the fitting until it reaches the marked

depth.

3) Clamping: The pipe and fitting assembly is securely clamped

using the machine's clamping mechanism. This ensures proper

alignment and contact between the pipe and fitting surfaces.

4) Welding: The electrofusion machine applies an electrical current

to the heating element in the fitting, generating heat that melts

the pipe and fitting surfaces. The current is applied for a

specific welding time determined by the manufacturer's guidelines.

5) Cooling: After the welding time elapses, the current is turned

off, and the molten material solidifies, forming a fused joint. The

joint is allowed to cool before releasing the clamping pressure.